Exploring the Versatility of Pneumatic Systems in Modern Industries

Pneumatic systems are vital components within industries. With the ability to use compressed air to perform a variety of tasks mechanically, these systems have advanced technology like no other. Their wide-ranging adaptability in life today guarantees the reliability and cost-effectiveness that modern businesses need, from automation to material movement. As the technology within pneumatic systems continues to evolve, they offer greater promise to industries around the world. This article examines the flexibility of pneumatic systems, their relevance, and their uses, as well as how companies, particularly those focused on industrial automation, are using them to serve the growing needs of the industry.

What Are Pneumatic Systems and How Do They Work?

Pneumatic systems are a medium of conveying information through moving parts by using compressed air. A pneumatic system enables machines and devices to perform the processes of moving, lifting, pressing, and controlling. Pneumatic systems feature compressors, cylinders, valves and treatment systems which are the core components. These systems create mechanical movements through the application of pressure to the air, thus providing the desired motion or force. The ease with which maintenance and modifications can easily be performed with pneumatic systems functions are few of the many reasons why these systems are crucial to modern industrial operations. Low maintenance costs, ease of use, and greater incorporation into business processes make pneumatic technologies popular for the majority of industrial automation systems. Frequently, pneumatic systems are selected due to their ever present usability for automation, ease of control, and power, which are essential for high speed and heavy duty work. Furthermore, they are useful within industries where the use of hydraulic and electric systems is restricted due to issues of space, safety, or power availability. Additionally, the low operational costs and minimal risks of overheating makes these systems ideal for 24/7 operations.

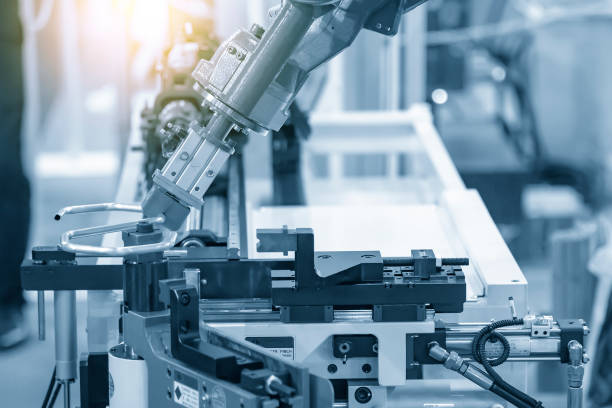

The Role of Pneumatic Systems in Automation

In today’s industrial context, automation has become an essential tool for increasing productivity, and it is clear that the pneumatic system is an integral element of it. These systems are applicable in controlling machine movement, robotics as well as assembly lines, to mention but a few. For example, pneumatic cylinders are incorporated in automated production lines to efficiently transfer components and supplies through a production cycle from one position to the next. Furthermore, Pneumatic motors are employed to adjust the position of the robotic arms, enabling the accurate performance of sensitive assembling functions. Many pneumatic companies specialize in designing and providing automated solutions that utilize pneumatic systems, allowing industries to boost efficiency and productivity. The use of automated pneumatic systems will result in increased productivity, decreased reliance on human beings, and enhanced workplace safety. Pneumatic systems are particularly important in very sensitive and fast moving industries such as automotive or electronics. Repetitive processes in bulk manufacturing require performance by the machine with utmost accuracy. Additionally, the incorporation of controls and sensors into pneumatic systems has made them more sophisticated because users are able to get immediate feedback that allows for adjustment of the processes being undertaken and minimizes mistakes.

The Versatility of Pneumatic Systems Across Industries

The versatility of pneumatic systems is demonstrated in the scope of tasks ranging from manufacturing, automobile, food processing, and even pharmaceutical. Due to their ability to achieve tasks quickly and with a high degree of accuracy and safety, these sectors have adopted these systems. For example, in manufacturing, the systems revolve around the control of machinery, lifting of heavy loads, and movement of different parts such as in the case of pneumatic conveyors that are used for material transportation in factories and warehouses. The automotive sector also heavily relies on these systems for the assembly of engines, transmissions, and brakes. When it comes to food processing, these systems find application in packaging, sealing, and material movement, while in the pharmaceutical sector, they are beneficial for automated filling of bottles and vials. Moreover, because these technologies can be made suitable for a wide scope of systems, industrial automation companies are continuously working on innovations to meet the needs of different fields. These technologies also fit into high hygiene standards as they are easy to clean and less prone to contamination than other systems.

Furthermore, the versatility of the pneumatic system enables quick and easy scaling of operations, making these systems ideal for both large and small businesses.

Advantages of Pneumatic Systems Over Other Technologies

When combined with features like regenerative air systems, pneumatic systems are energy efficient, making them powerful aids for various industries. They are also much simpler than electrical and hydraulic systems, as these systems contain more moving parts which result in them being less reliable. Unlike other technologies, pneumatic systems can be used in hazardous settings, as they do not produce sparks or heat. This makes them desirable in various industries that deal with flammable materials. Along with safety concerns, efficiency and flexibility are also major advantages which have made them one of the top choices for industrial automation companies. Because their components can be altered or replaced for a variety of uses and tasks, pneumatic systems have more uses than electric or hydraulic systems, especially in electrical pressing or lifting. They also have applications in medicine or electronics assembly as well, where precision is necessary.

Alongside the growing importance of sustainability and energy efficiency, pneumatic systems provide an environmentally friendly option for assistance to industries in fulfilling their environmental objectives.

Conclusion

Moreover, the unparalleled diversity of operational processes capable of being performed with the help of these systems makes pneumatic systems invaluable in contemporary industries. Ranging from production line automation to materials handling, pneumatic systems, to put it in one word, perform. These systems greatly enhance operational efficiency, safety, and accuracy. Automation companies will continue their efforts to incorporate these systems in different fields, and, consequently, the automation, productivity and sustainability will grow with the use of these systems. Without a doubt, the versatility and ingenuity of pneumatic systems guarantees their relevance in the industrial setting these days and greatly assists industries in fulfilling market requirements with effective performance. The evolution of pneumatic systems will stem from modern technologies, which will further assist industries to remain competitive and responsive to contemporary challenges.